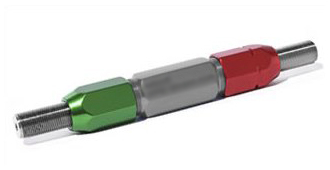

Thread Plug Gauge

Thread Gauges

- Thread plug gages are used to check an internal threaded hole. The most common thread plug classifications are:

- 2B which is a general purpose class of fit.

- 3B which is used to check parts with' 'closer" tolerance requirements.

Working thread plugs are to be used in an internally threaded hole and are not to be used to check a ring gage. The part being checked is generally acceptable when the NOGO work plugs does not enter more than 11/2 to 3 turns dependent upon customer specifications and the GO work plug freely enters the threaded hole in its entire length. In addition to the passing the GO/NOGO working plug gages; the minor diameter must be checked by an alternate method. GO/NOGO Plain Plug Gages are one of the simplest methods of checking the minor diameter, but many other tools can accomplish a similar function.

The GO work plug gage is usually made longer than the NOGO because the GO must enter the part fully where the NOGO should not enter more than 3 turns. The GO work plug gage checks the full functional fit of the thread at its maximum material condition, except the minor diameter.

The NOGO work plug gage has the major diameter truncated so that it only tests the pitch diameter. The NOGO working plug gage pitch diameter is larger than the GO pitch diameter, but the NOGO working plug gage major diameter is smaller than the GO major diameter.

There are three (3) styles of working plug gages: Taperlock; Reversible; Trilock.

The taperlock style consists of a GO and/or NOGO member(s). The GO member is longer than the NOGO and has a chip groove (in larger sizes) which not only adds to ease of identification but also assists in clearing obstructions.

Double End Thread Plug Gauge Taper Lock Design

The reversible thread plug gage also consists of a GO and NOGO member(s). Both members are straight and afford the gage user double the life by simply reversing the gage member(s), turning the worn portion into the handle.

Double End Thread Plug Gauge Reversible Design

The trilock design is best suited for large size thread plug gages (1-1/2 inches and up), but is available in sizes as small as 3/4 inch. Consisting of a GO and/or NOGO member(s), the trilock has a bolt fastening system to support the size and weight. A chip groove is provided on the Go member for ease of identification and clearing obstructions.

Trilock Design

Proper selection of the drill and tap is required to insure that the tapped hole will meet tolerance limits. The GO member not entering the hole may be indicative of incorrect tooling, improper setup and/or burrs. If the NOGO member enters the threaded hole of the part more than three (3) turns it is possible the wrong size threading tool is being used or you have a "bell mouth" hole condition.

Gages are normally manufactured and inventoried to class "X" tolerances which refers to pitch diameter, major diameter, lead tolerances and thread angle tolerances. Class "W" tolerances which are recommended for closer product tolerances or final inspection are also available upon request. Both classifications, "X" and "W", are gage manufacturers' tolerances and not the limits.